With the advancement of the global "carbon neutral" goal, photovoltaic power generation, as the core pillar of clean energy, is developing an unprecedented speed. As the "brain" of the photovoltaic system, the reliability, efficiency, and service life of the inverter directly affect the power generation benefits the entire power station. Currently, inverters are developing towards higher power density, further miniaturization, and a broader range of application environments (such as residential, industrial and rooftop, harsh Gobi, coastal areas, etc.). This trend poses extremely demanding challenges to the long-term stable operation of the core components inside the inverter-printed boards.

一. PCBs for photovoltaic inverters in the market mainly face the following issues:

1. High and low cycle shocks: The inverter generates a large amount of heat during operation, which cools down at night or in cold weather, experiencing drastic temperature fluctuations daily (-40℃ to85℃ or even higher), causing traditional protective materials to age, crack, and lose their protective function.

2. Moisture and dew: Especially in coastal or high humidity areas, moisture in the air can condense on PCB boards, causing migration, short circuits, corrosion of metal parts, and permanent damage.

3. Chemical corrosion: Sulfur compounds, salt fog, and other corrosive substances in the of industrial areas can erode delicate electronic components and solder joints.

4. Electrical insulation requirements: Inverters contain high voltages internally, demanding that protective materials have excellent insulation to prevent arcs and breakdowns.

5. Flame retardant safety requirements: As electrical power conversion equipment, inverters must meet strict flame retardant standards to the spread of fire in the event of a malfunction.

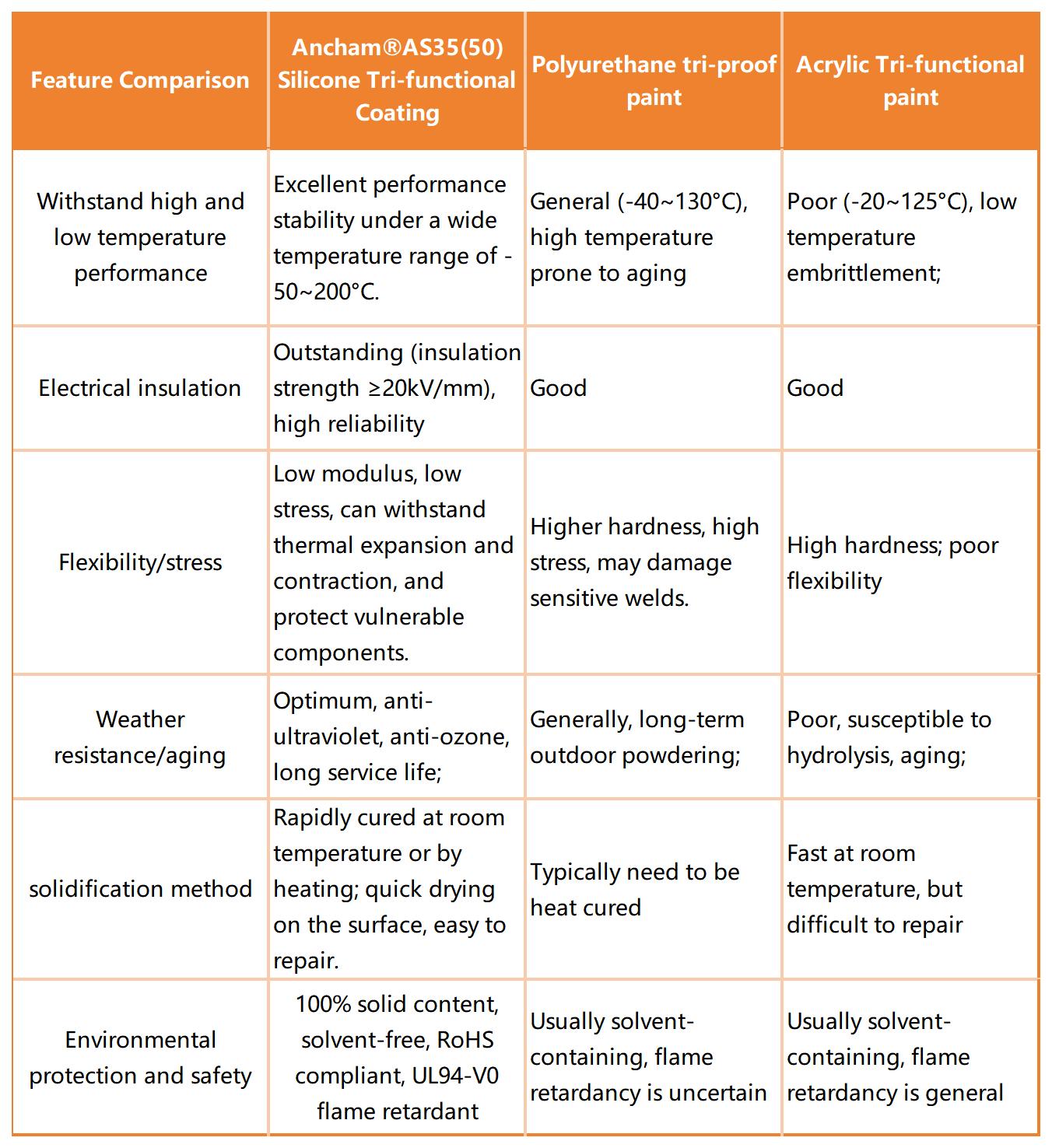

Traditional conformal coatings such as acrylics and polyurethanes often struggle to meet these stringent requirements across board in terms of temperature resistance, insulation, and aging resistance.

二. Product Comparison and Core Advantages of Ancham® AS35(50):

Compared with other types of conformal coatings, Ancham AS35(50) silicone conformal coating, with its unique chemical properties, has become an ideal choice for PCB protection of photovoltaic inverters.

三. Core advantages of Ancham® AS35(50) applied to photovoltaic inverters:

• All-round environmental adaptability: Its wide operating temperature range (-50~200℃) can easily cope with high and temperature shocks inside the inverter, ensuring that the protection function does not fail under extreme climates.

• Reliable electrical safety guard: Excellent insulation strength (≥20 k/mm) and volume resistivity (7.0x10¹³ Ω.cm) provide a strong insulation barrier for high-power density inverters, effectively preventing-voltage electric arcs and leakage risks.

• Durable physical protection: Excellent adhesion (zero grade according to the hundred-grid method) and low stress, high elasticity allow it to adhere tightly to the surface of PCBs and components, expanding and contracting with the base material without cracking or detaching, effectively resisting vibrations and mechanical stresses.

• Efficient production and maintenance: The low viscosity and easy flow characteristics are suitable for spray coating process, making it easy to achieve automated production and cover complex boards. It supports UV fluorescent detection, which is convenient for quality inspectors to check the uniformity and integrity of the coating. For boards that are not completely cured, solvents be used to easily remove them, which is convenient for rework and reduces production costs.

四.Specific application scheme of Ancham® AS35(50) in photovoltaic inverters:

1. Application parts:

• Main control board: Protect the core processor, memory chip, etc., against signal interference or crash to humidity and corrosion.• Drive board: Protect the driving circuit of IGBT/MOSFET, ensuring precise triggering of power switching devices.

• Sampling and sensing board Protect the interface circuit of current, voltage sensors, ensuring sampling accuracy and improving system efficiency.

• Auxiliary power board: The power module that supplies power to the low- chips inside the inverter, short circuit fault needs to be prevented.

2. Coating process:

• Recommended process: Automated spraying. Given the large production and complex PCB layout of photovoltaic inverters, automated spraying can achieve uniform, consistent, and efficient coating, and precisely control the thickness of the paint (suggested around 100μm).

• Pre-treatment: Strictly follow the user guide, clean and dry the PCB board before coating thoroughly remove dust, moisture, and flux residue, which is key to ensuring excellent adhesion.

• Curing conditions: To improve production efficiency, it is recommended to use a curing scheme. For example, baking at 80℃ for 2 hours can be fully cured, greatly shortening the production cycle. If production needs, it can also cured at room temperature for 24 hours.

3. Quality control:

• Utilize the built-in UV fluorescence characteristics of the product, use an ultraviolet lamp toradiate after coating, quickly check whether the coating is complete, whether there is leakage or uneven thickness.

In today's era of high-quality development of the photovoltaic industry, choosing a high-performance and highly reliable conformal coating is crucial enhancing the market competitiveness of photovoltaic inverters. Ancham® AS35(50) conformal coating, with its excellent thermal resistance, electrical insulation,, and flame retardancy, provides all-round "armor" protection for the PCB boards of photovoltaic inverters, significantly improving the product' lifespan and reliability under harsh conditions, reducing the rate of after-sales faults, and creating greater value for customers.