The urgent demand for circuit protection in the era of precision electronics

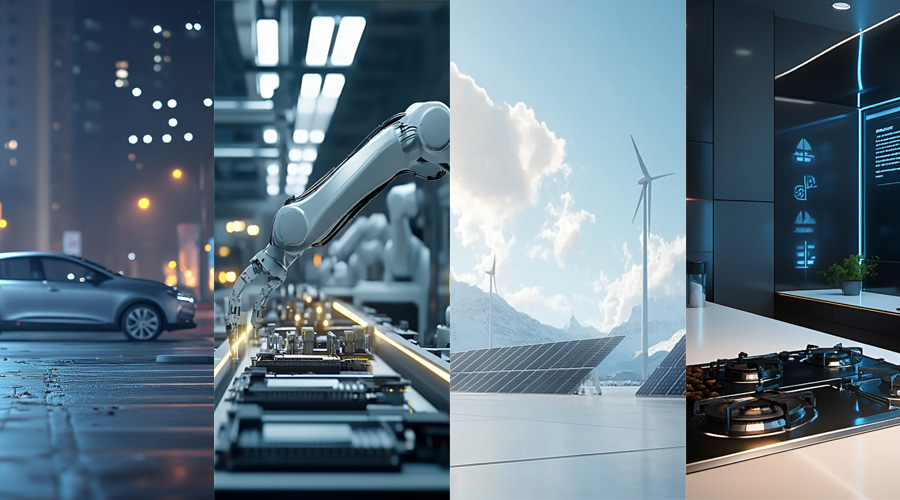

With the rapid development of electronic technology, the printed circuit board (B), as the "nerve center" of electronic devices, directly determines the overall performance and lifespan of products. However, complex application scenarios—from the high-temperature vibration the car engine compartment, the sun and rain exposure of outdoor new energy equipment, to the dust and humidity of industrial sites, and the frequent temperature changes of household appliances—are constantlyoding the precision circuits. Moisture, dust, chemical corrosion, mechanical stress, and high-temperature impact can all trigger circuit short circuits, signal interference, or even permanent damage leading to equipment failure and posing significant economic and safety risks.Therefore, coating a reliable protective film on key electronic components, namely "three-proof paint" (waterproof dustproof, and corrosion-proof), has become an indispensable process link in modern electronic manufacturing. The market urgently needs a high-performance three-proof paint material that can comprehensive protection, yet also has excellent construction adaptability, environmental safety, and can meet the rapid pace of production.

Ancham AS35(50) Silicone Tri-functional Paint

Ancham AS35(50) single-component organic silicone conformal coating anti-corrosive paint provides all-round circuit protection solutions for high- electronic devices in response to the above challenges, with its unique material science and engineering design.

1. Outstanding product features, directly addressing application pain points

• Environmental safety and efficient construction: As a 10% solid content, solvent-free product, AS35(50) has no volatile matter during construction and curing, complying with strict environmental regulations such as RoHS ensuring the health of production personnel. Its low viscosity and easy flow characteristics make it very suitable for automated spraying or flow coating, capable of quickly and evenly covering complex circuit boards, high-density component gaps, and it is easy to defoam, forming a smooth and flawless transparent protective layer after curing.

• Flexible curing mechanism: product supports room temperature curing (about 24 hours) and rapid heating curing (only 2 hours at 80℃), providing flexible options for customers with production cycles and energy consumption requirements, greatly improving production efficiency.

• Comprehensive protection performance:

Electrical insulation: Extremely high insulation strength (≥20 kV/) and volume resistivity (7.0x10¹³ Ω.cm) can effectively prevent arc breakdown and leakage between circuits under high voltage, ensuring the integrity of signal.

Wide temperature resistance: The broad working temperature range from -50℃ to 200℃ allows it to easily cope with extreme high and low temperature cycles, stable operation of equipment in harsh cold or hot environments.

Physical reliability: Moderate hardness (Shore A 30±5) and excellent adhesion (zero grade the scratch test) mean that the coating is flexible and strong, effectively buffering the stress caused by vibration and thermal expansion, avoiding cracking or falling off.

Highest safety standard Complies with UL94-V0 flammability rating, which can effectively prevent the spread of fire even in extreme fault conditions, providing a vital safety barrier for end products.

• Tracability and easy maintenance: The coating has built-in UV fluorescence characteristics, which are convenient for quality inspection on the production line, ensuring that the coating is uniform complete. For boards that are not completely cured, it can be easily removed with solvents, facilitating rework and maintenance, and reducing production costs.

Typical industry applications

The superior performance of Ancham AS35(50) makes it the preferred protective material for multiple key industries:

• Automotive electronics: applied to engine control units (ECU), in-vehicle sensors, battery management systems (BMS),., to protect them from high temperatures, engine oil, vibrations, and sudden temperature changes, meeting automotive-grade reliability requirements.

• New energy and energy storage: used in control boards for photovoltaic inverters, wind power converters, and energy storage systems (BESS), providing long-term resistance to weather, insulation, anti-corrosion protection, ensuring energy conversion efficiency and system safety.

• Industrial automation: provides protection for key equipment such as PLCs, servo drives, and robot controllers, against dust, humidity, oil mist, and electromagnetic interference in factory environments, ensuring the continuous and stable operation of production lines.

• Communication infrastructure: protects circuit boards communication equipment such as 5G base stations, network switches, and data center servers, enhancing their long-term reliability under outdoor variable climate conditions.

• High-end consumer: applied to intelligent control boards for high-end household appliances, motor drive boards for power tools, etc., to improve product durability, safety, and market competitiveness.

Ancham AS35(50) conformal coating is more than just a coating, it is a systematic solution that enhances the reliability, safety, and of electronic products. It not only balances excellent construction workability with top-notch protective performance, but also helps manufacturers address the challenges of increasingly demanding application environments, making it a trustworthy in high-end electronic manufacturing.