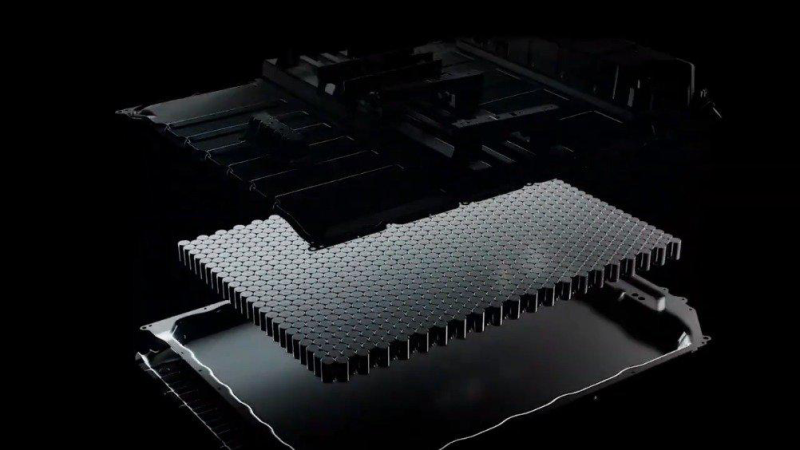

With the development of the automotive industry towards electrification, intelligence, and lightweighting, automotive headlights have evolved from traditional lighting functional components into a complex that integrates lighting, communication, safety warnings, and aesthetic design. The popularization of LED, adaptive driving beam (ADB), and even intelligent digital headlights has put forward high requirements for the sealing, structural strength, and long-term reliability of headlights.

Against this backdrop, PUR hot-melt adhesive is gradually becoming one of the preferred materials for bonding and sealing automotive lamps, owing to its excellent comprehensive. Compared with traditional hot-melt adhesives, silicone, or epoxy resin, PUR hot-melt adhesive integrates the construction convenience of the hot-melt process the excellent durability after reaction curing. Its development shows the following trends:

• Superior weather resistance: Endures cycles from extreme cold to scorching heat, ensuring long-term adhesion and waterproofing.

• Enhanced efficiency: Suitable for automated dispensing, with the right open time to achieve precise assembly and quickly build initial strength.

• Broader substrate compatibility: Reliably bonds a of materials including PC (polycarbonate) lenses, PMMA (acrylic), electroplated parts, metal enclosures, and ceramic circuit boards.

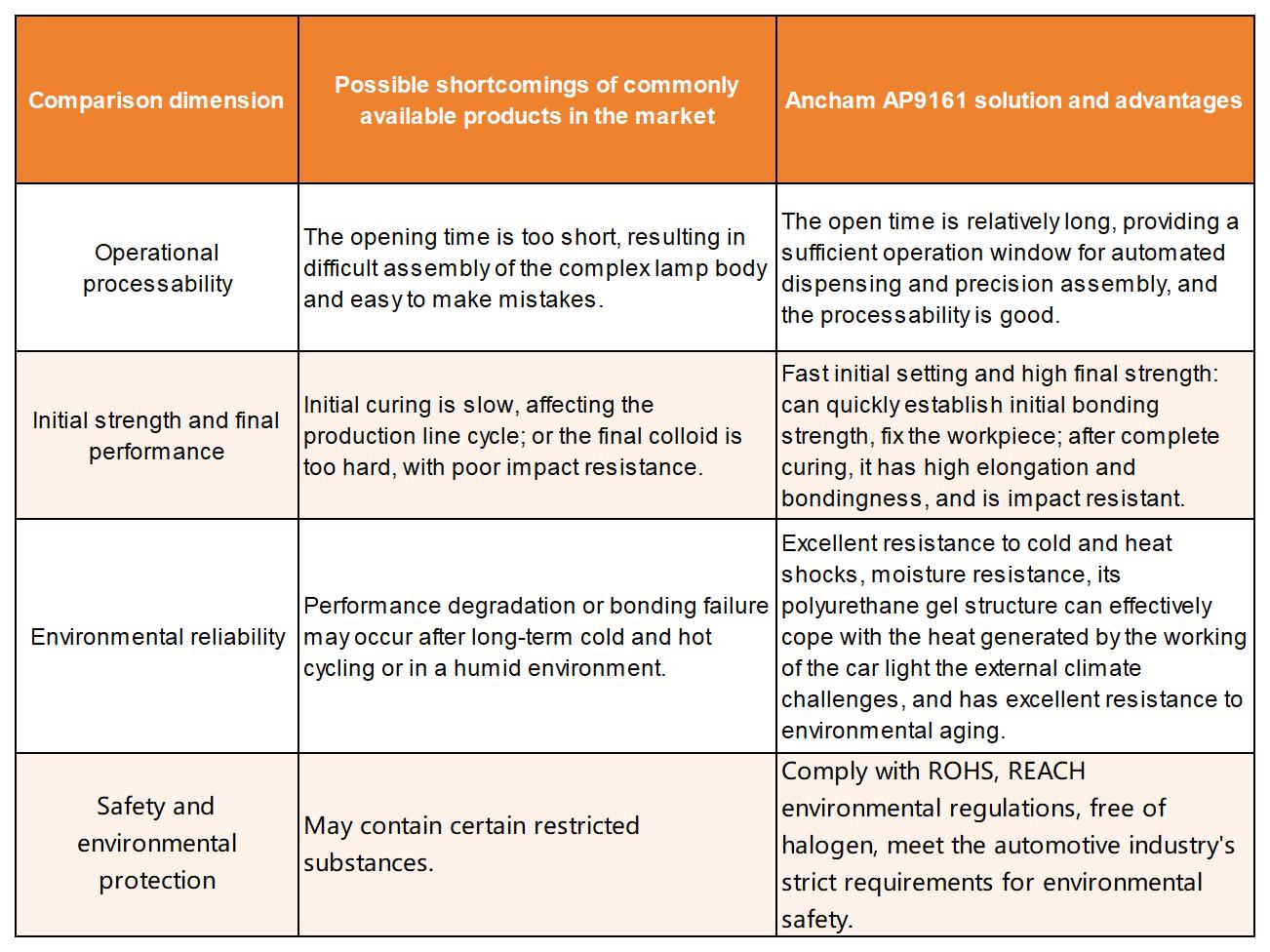

一、Market competitive product comparison Ancham AP9161

In the current PUR hot melt adhesive market, there are differences in open time, curing speed, and final mechanical properties among different products. Some products may operational tolerance for quick curing, or lack in bonding toughness. Ancham® AP9161 is a high-performance product developed with a deep understanding of these pain points, and its core advantages are as follows:

二、Core features of Ancham AP9161 in automotive headlight applications

Based on the above advantages, AP9161 provides a highly competitive bonding and sealing solution for the manufacture of automotive lights, with its application characteristics particularly prominent:

1. Excellent substrate compatibility, one glue for multiple uses

AP9161 is designed for bonding a variety of substrates, including plastics, metals, ceramics. This means that in automotive lighting applications, whether it is bonding PC lenses to PP housing, fixing LED modules to metal heatsinks, or bonding electroplated trim, AP9161 can provide stable and reliable bonding force, simplifying material management.

2. Optimized curing characteristics, enhancing production efficiency

• Suitable for automation: The single-component, 100% solids nature the product makes it highly compatible with automated gluing equipment, ensuring consistent and efficient coating application.

• Balanced cure rate: Under typical conditions of 55% relative humidity it achieves rapid initial setting to meet the line cycle requirements, while reaching full cure in 7 days for optimal performance. It is worth noting that low temperatures and high humidity accelerate the, a property that can be effectively utilized in specific processes requiring swift curing.

3. Excellent durability ensures safety throughout the entire life cycle of the headlight

• Cold and heat resistance: The headlight generates heat during operation ands down to ambient temperature after being turned off. The high elongation of AP9161 effectively absorbs the stress caused by thermal expansion and contraction of different materials, preventing and sealing failure.

• Mechanical impact and vibration resistance: The toughness of the sealant itself can buffer the vibrations and impacts from the road, protecting the internal precise electronic and components.

• Aging resistance: It can resist long-term aging caused by environmental factors such as ultraviolet radiation and humidity, ensuring the sealing integrity and functional safety of thelight throughout the entire vehicle life.

Ancham® AP9161 PUR hot melt adhesive, with its excellent process adaptability, powerful final performance and superior resistance to the harsh conditions of headlights, has become the ideal choice for bonding and sealing modern automotive headlights, especially high-end intelligent headlights. It not only meets the current production efficiency requirements, but also provides a solid guarantee for the long-term reliability and safety of headlights, and is a key material partner to help headlight technology continue to innovate