Polyurethane reactive hot-melt adhesive (PUR), as an important innovative product in the field of adhesives, combines the dual advantages traditional hot-melt adhesives and reactive adhesives. It forms a high-strength polyurethane colloid with a network structure by triggering the crosslinking reaction the moisture in the air, and is gradually becoming the first choice to replace traditional bonding solutions in various high-end manufacturing industries.

Ancham AP9161 is a one-component moisture-curing hot-melt adhesive launched by Anshun New Material. It a 100% solid content, is environmentally friendly, and complies with RoHS and REACH standards, free of halogen. Its unique formula design makes it exceptionally well in terms of open time, curing speed, and bonding strength. After curing, the product forms a high-strength polyurethane body, with high elongation bonding toughness, which can effectively resist cold and heat shocks, humid environments, and mechanical vibrations, and has outstanding aging resistance. With its excellent performance and wide range of applications, product provides efficient and reliable bonding solutions for industries such as electronic digital devices, automotive manufacturing, and smart wearable products.

Core product advantages

Ancham®AP9161 polyurethane reactive hot-melt adhesive from Yaskawa New Materials, with its breakthrough technological innovation, has set new performance benchmark for the industry:

1. Excellent process adaptability

• Single-component moisture-curing system, 100% solid content, no need for mixing ratio

• time up to minutes, perfectly compatible with automated gluing process

• Initial curing presents high bonding strength, greatly improving production efficiency

2. Extraordinary durability

• After curing, it exhibits a high elongation at break (>400%) and excellent bonding toughness

•standing resistance to cold and heat shocks, and moisture and heat aging performance

• Withstands mechanical impact and vibration, and its weather resistance far exceeds industry

3. Wide material compatibility

• Excellent bonding performance on a variety of substrates, including plastics (PC/ABS/PP, etc.), metals, cerics, etc.

• Complies with RoHS, REACH environmental standards, free of halogens, and meets export requirements.

Typical application scenarios

1.Consumer electronics field

• Smartphone/laptop display edge bonding and sealing

• Structural parts fixing of smart wearable devices

• Optical components of VR/AR devices

2.Automotive manufacturing field

• Sealing of car headlights (withstanding high temperature and high humidity environment)

• Fixing and protection of in-vehicle control system

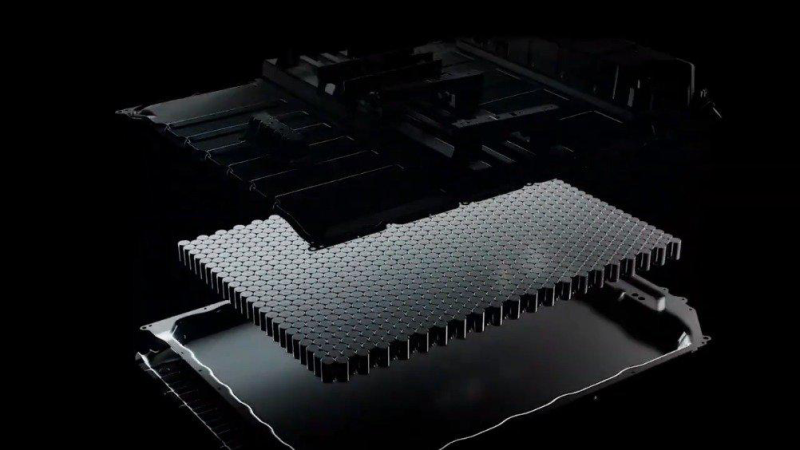

• Encapsulation of new energy vehicle battery pack

3.Industrial electronics field

• Communication base station control panel sealing

• Industrial control equipment structure bonding

• Outdoor electronic equipment waterproof sealing

The launch of Ancham AP9161 not only reflects the company's profound technical accumulation in the field of polyurethane materials, but also a reliable bonding solution for the smart manufacturing industry. In the future, Ancham New Materials will continue to focus on the research and development and application of innovative materials, providing more highquality options for the upgrading of global manufacturing.