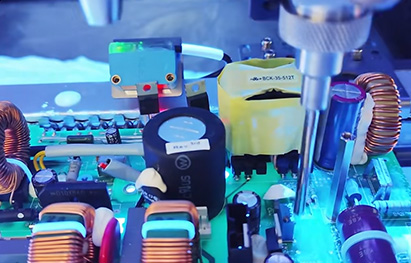

In the field of electronic manufacturing, conformal coating is a critical material that protects printed circuit boards from moisture, salt spray, mold, and chemical erosion. Selecting appropriate conformal coating is essential for the long-term reliability of products.

Ancham® AP9502 is a single-component polyurethane-modified alkyd resin conformal coating designed for electronic protection. This contains no benzene-based solvents, ensuring environmental safety. It can be cured at room temperature or accelerated with heat, has good wetting on the substrate surface, and bubbles after curing. It is suitable for various processes such as dipping, spraying, and brushing, providing uniform protection on uneven surfaces and effectively resisting moisture, chemicals, and-temperature environments. After curing, AP9502 can be inspected with UV light for quality control and rework, making it widely used in various electronic and electrical PC circuit boards.

Ancham® AP9502 Core Product Features

Based on the technology of modified alkyd resin with polyurethane, Ancham® AP902 exhibits excellent comprehensive performance:

• Excellent high-temperature resistance: With a temperature range of -40℃ / 135℃, the performance is stable, suitable high-temperature working environments such as automotive electronics or industrial equipment.

• Outstanding electrical insulation performance: Even in humid conditions, the film coating can maintain high insulation, with a resistivity of 2×10¹⁵ Ω·cm and a surface resistivity of 2.6×10¹⁵ Ω, ensuring circuit safety.

• protection and safety: Free from benzene-based substances, it meets environmental requirements; the product uses environmentally friendly solvents, but ventilation and fire prevention are needed to ensure safe.

• Easy construction and inspection: With moderate viscosity (12-25 seconds for a 4-cup at 25℃), 38-4% solid content, the construction is smooth; after curing, it can be detected by UV, which is convenient for process control.

• Strong adhesion and durability: With pencil hardness of 3-4H, the adhesion reaches 0 grade (cross-cut method), water absorption rate ≤0.15%, and excellent resistance, it provides long-term protection.

These characteristics make the AP9502 ideal for protecting PCBs from moisture, salt spray, and mold while enhancing the reliability and lifespan of the equipment.

Typical applications and performance advantages

The AP9502 is widely used in various electronic and electrical equipment:

• Industrial control systems: Protect PCBs from harsh environments to ensure stable operation.

• Automotive electronics: Withstand high temperatures and vibrations to ensure safety.

• Consumer electronics: Improve insulation to extend product life.

• Communication equipment: Prevent moisture and corrosion to reduce failure rates.

AP9502 offers advantages such as:

• Versatile protection: Provides comprehensive coverage through conformal coating, covering complex components.

• Process: Supports dipping, spraying, and brushing, adapting to different production needs.

• Cost-effective: Room-temperature curing saves energy, and easy repair reduces maintenance.

Compared to other types, Ancham® AP9502 combines the chemical resistance of polyurethane with the easy workability of alkyd, achieving balanced performance: resistant to high temperatures, good insulation, free of benzene solvents, and suitable for a variety of coating processes. Not only does AP952 provide reliable protection against harsh environments, but it also takes into account the production needs of environmental protection, safety, and ease of use, making it an ideal choice for enhancing the and lifespan of electronic devices.