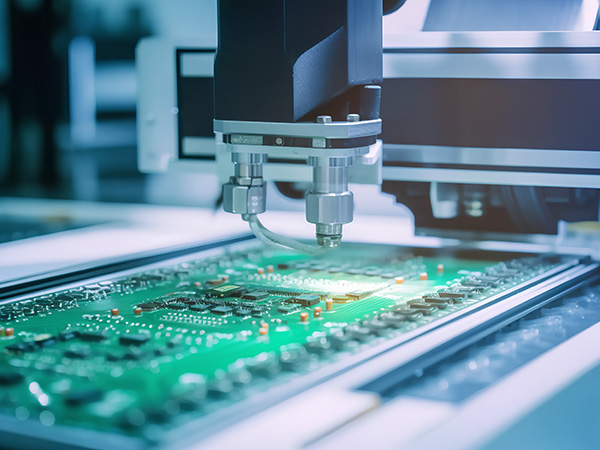

As electronic devices develop towards high power, high density and high reliability, the protection of printed circuit boards (PCBs) faces higher challenges. As a key to ensure the stable operation of PCBs in harsh environments such as humidity, salt fog and chemical corrosion, the performance of conformal coating directly affects the life and quality of end products.

The selection of conformal coating is crucial for ensuring the long-term stable operation of PCBs. Ancham® AP9502, a high- solution launched by Yaskawa New Materials, is tailored to address the pain points of the current market. With its unique material formula, this product has achieved breakthroughs in multiple key indicators, providing PCB design and manufacturing engineers with a more competitive optimization solution.

Challenges and demands of the current PCB conformal coating market

Traditional conformal coating materials have their own advantages and disadvantages. Epoxy resin conformal has high hardness and good chemical resistance, but it has large internal stress, poor protection for sensitive components, and difficult repair. Silicone resin conformal coating has good elasticity and wide resistance range, but it is prone to dust adhesion, relatively weak adhesion, and may interfere with subsequent welding processes. In addition, some products containing benzene-basedvents also put forward higher requirements for the health of production personnel and environmental protection.

Ancham AP9502: Breaking the deadlock with technological advantages

Ancham AP9502, as a single-component polyurethane alkyd resin coating, exhibits significant advantages from the material source to the final performance, precisely responding to the core needs of the market:

1. Outstanding thermal stability ensures reliable performance in extreme temperatures: AP9502 can endure a temperature range from -40℃ to 35℃, maintaining stable performance even at high temperatures. This characteristic makes it highly suitable for PCB protection in high-temperature environments such as engine compartments and power modules, avoiding the risk of coating failure due to temperature fluctuations.

2. Excellent electrical insulation properties provide protection against humid conditions: Even in film-coated form, AP952 can still offer extremely high volume resistivity (2x10¹⁵ Ω.cm) and surface resistance (2.6x10¹⁵ Ω.cm) ensuring the insulation safety between circuits in high-humidity environments, preventing short circuits and leakage faults, and significantly enhancing product reliability.

3. Balancing environmental and safety concerns, aligning with green manufacturing trends: The product is free from benzene-based substances, offering safer choice for production operators and end-users, and meeting high standards for production safety. It provides a balanced and stable coating material from three perspectives: performance, process, and material.

4. Outstanding process adaptability and traceability: AP9502 supports multiple coating processes, including immersion, spraying, and brushing, with a fast surface speed, which can adapt to different production rhythms. Once cured, it allows for UV inspection, greatly facilitating the inspection and traceability of coating quality during the production process, enhancing control levels.

5. Comprehensive protective performance: This product features 0-level adhesion (per the cross-cut test) and an extremely low water absorption rate (0.15%), indicating that it can firmly adhere to the surface of PCBs and components, and effectively resist the erosion of moisture, salt fog, and chemical substances, all-around protection for PCBs.

Product feature comparison in the market: The differentiated advantages of AP9502

Compared with the common types of three-proof paint as acrylic, silicone resin, etc., the polyurethane modified technology of AP9502 shows unique comprehensive advantages:

• Compared with acrylic three-proof paint:rylic paint has the advantages of low cost and fast surface drying, but its heat resistance is usually poor (generally below 125℃), and its chemical resistance and resistance are weak. AP9502 surpasses in heat resistance, mechanical strength, and chemical resistance while maintaining good operability, making it more suitable for applications with strict.

• Compared with silicone resin three-proof paint: Silicone paint has excellent heat resistance, but its inherent surface energy is low, which may lead to adhesion issues and prone to dust generation. It is limited in some occasions with high cleanliness requirements (such as automobile sensors). AP9502 provides stronger adhesion (0 grade) hardness, forming a more dense protective film, while avoiding the pollution risk that may be brought by silicone materials.

Applicable to a wide range of fields, empowering high reliability electronic manufacturing

Ancham®AP9502 conformal coating is typically used in variousB boards with extremely high reliability requirements, such as automotive electronics, industrial control, power equipment, communication base stations, outdoor displays, and consumer electronics. It can effectively protect components harsh environments, extend the service life of electronic products, and reduce failure rates. In the era of intelligence and the Internet of Things, the application scenarios of electronic devices will become more and diverse, and the requirements for PCB protection will also increase. Ancham®AP9502 polyurethane conformal coating, with its comprehensive advantages such as high temperature, high insulation, environmental safety, etc., will provide a solid guarantee for electronic manufacturing enterprises to create more market-competitive high-reliability products