With the dual trends of soaring chip computing power and device miniaturization, the electronics industry is facing an unprecedented physical contradiction: the confrontation between rigid structural design dynamic environmental stress. Thermal cycling-induced material deformation, micro-cracks caused by high-frequency vibrations, and circuit corrosion induced by moisture permeation—the static protection of traditional sealants has become difficult to cope with. The birth of Ancham AS3465 is precisely to break through this industry dilemma with "flexible dynamic sealing"

Innovative essence: from "filling gaps" to "stress symbiosis"

Ancham AS3465 breaks through the passive filling of traditional sealants, reconstructing the protection logic through three core technologies:

1. Thermal stress buffer

With a fracture elongation rate ≥600% ( times the industry average), it can absorb the expansion difference between the PCB board and the metal case caused by a 200℃ temperature difference, solving the problem of fracture of solder joints.

2. Vibration energy conversion layer

The flexible rubber with a hardness of 38A Shore will convert mechanical vibration into elastic deformation, precision components (such as MEMS sensors) from impact failure.

3. Electrochemical barrier

With a volume resistivity of 3.41×10¹⁴·cm and an insulation strength of >15kV/mm, it forms a "molecular-level anti-seepage network", blocking electrochemical corrosion caused by migration of electrolyte.

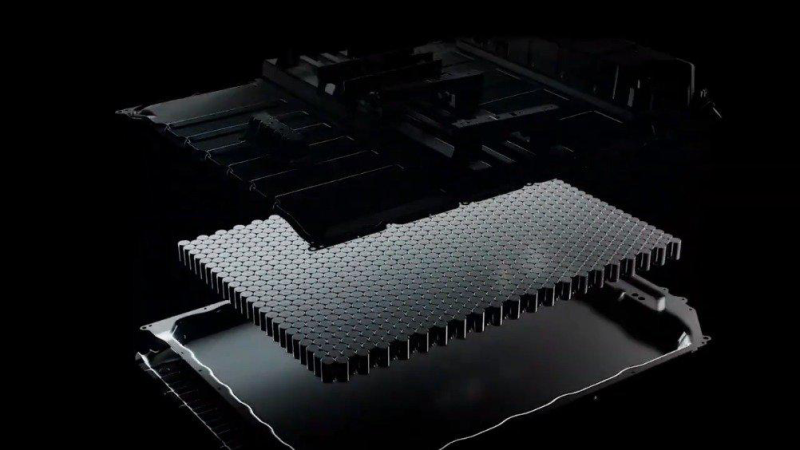

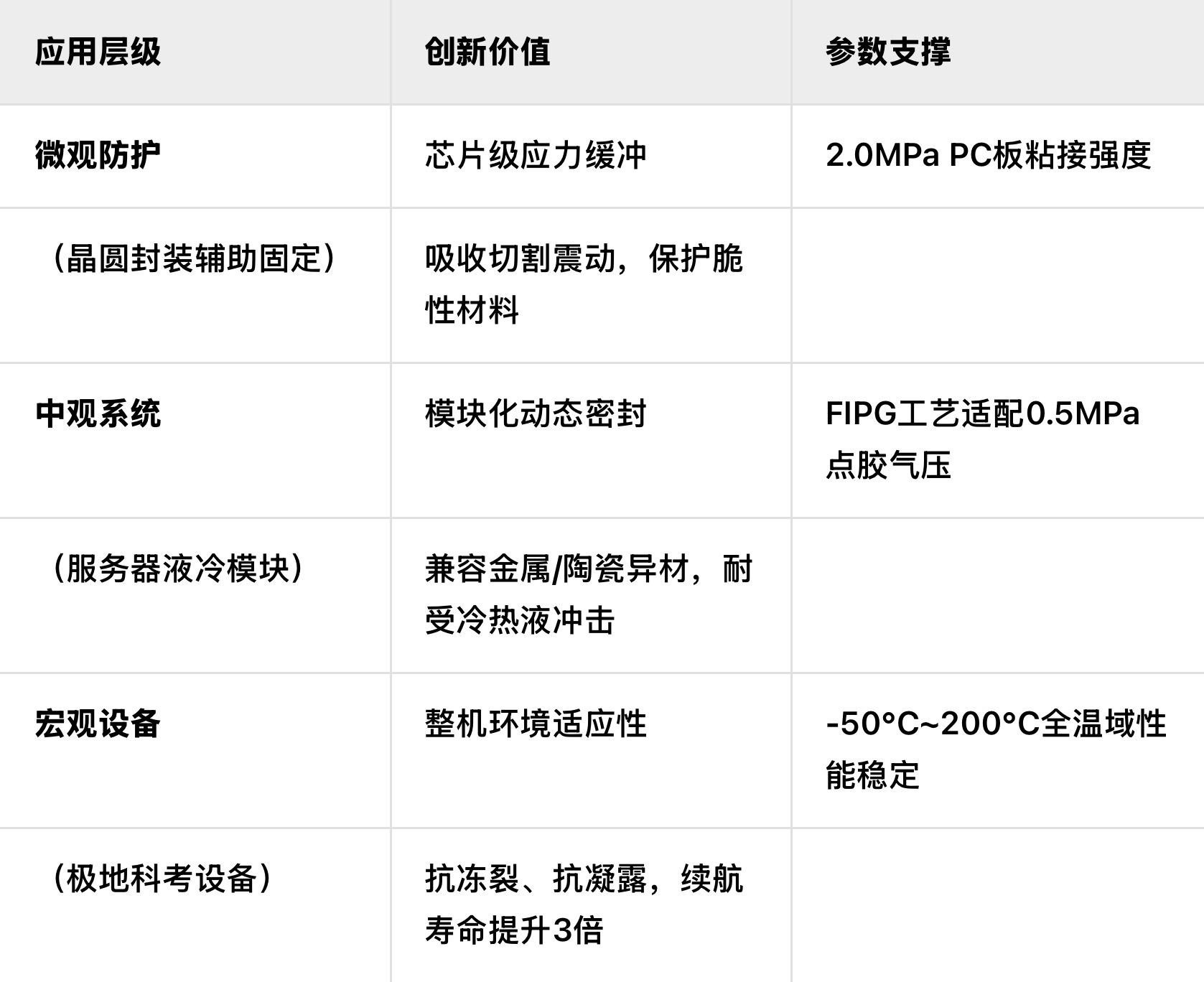

Full-scene coverage of the electronic industry - from nanometer to meter-level protection

Reconstructing the production logic: when "slow curing" becomes an advantage

Unlike traditional fast-curing adhesives that prioritize, the 7-day curing cycle of Ancham AS3465 is imbued with new value:

• Molecular self-arranging technology: The curing process allows the siloxane chains to crosslink orderly, forming a dense network (compared to a 90% reduction in porosity for fast-c adhesives); • Stress pre-release window: After 48 hours of construction, a critical period of deformation, the adhesive dynamically adjusts internal stresses to prevent cracking on.

Sustainability revolution:the hidden value of solvent-free formulations

The zero-halogen/solvent-free characteristics of Ancham AS3465 only meet RoHS but also bring about an industry chain upgrade:

•Chip compatibility: Avoiding solvent volatilization residue that corrodes BGA solder balls (im the yield rate by 5.3%);

•Carbon neutrality contribution: A 300ml single bottle reduces packaging materials by 37%, and carbon emissions reduced throughout the entire life cycle;

•Ergonomics: The construction process has no irritating odor, and factory ventilation energy consumption decreases.

The essence of Ancham AS3465 is to clad electronic devices in a flexible armor that breathes. It does not pursue absolute strength, instead resolves environmental stress with dynamic adaptability—just like the self-regulatory mechanism of biological tissues. As the electronics industry moves towards quantum computing and space electronics, this philosophy "combining hardness and softness" may become the core paradigm for the reliability of the next generation of devices.