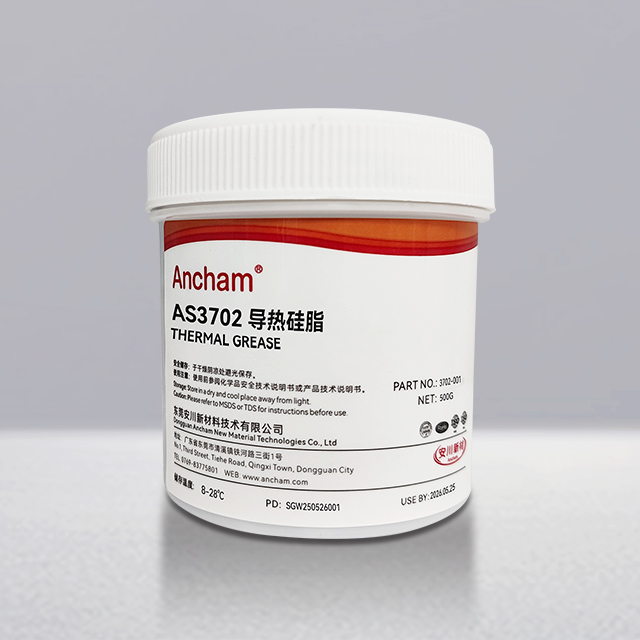

In an era of explosive growth in 5G base stations, electric vehicles, and high-performance computing chips, heat dissipation failure in electronic devices has become major industry pain point—traditional thermal grease drips and contaminates circuits, thermal pads have too high thermal resistance, and high-temperature powdering leads to a sharp decline in thermal efficiency... The birth of Ancham® AS3702 thermal grease is providing solutions to this "heat dissipation war"!

Overheated electronic devices = performance degradation? Traditional thermal conductive materials sag, crack, and have high thermal resistance? Ancham® AS370, with thixotropic locking technology+2.5W/m·K ultra-conductivity, breaks the heat dissipation problems in high-temperature vibration scenarios, anddefines the reliability of thermal management for electronic components!

Ancham AS3702 thermal grease – directly addressing the four major pain points of the industry, performance breakthrough

1. Seismic anti-sag flow, ending the "drip nightmare"

Ordinary silicone grease on the market becomes thin and flows at high, which can easily trigger the risk of circuit short circuit. AS3702 achieves zero sag after application through thixotropic gel technology (test standard: 20℃/24h oil separation ≤ 0.5%), and it still locks in place stably even in the scenario of vehicle vibration and high-frequency movement of printer head.

2. High thermal conductivity ultra-low thermal resistance

Compared with thermal pads (usually with thermal conductivity ≤ 2.0 W/m· and a thickness of more than 0.5mm), AS3702 only needs a thin coating (0.1mm level) to break through the interface thermal bottleneck, increasing the heat conduction efficiency of CPU and IGBT modules by 30%!

3. Withstands extreme temperatures without cracking or hardening

Ordinary silicone grease hardens at -20℃ and cracks and powdering at 10℃; AS3702, after being frozen at -50℃ and baked at 200℃ (certified by ASTM D5470, does not harden or melt and drop, ensuring long-term stable operation of LED car lights and power modules.

4. Double insurance of insulation safety

Excellent electrical insulation (dielectric strength > 15kV/mm) and non-toxic and noncorrosive properties, passed RoHS/REACH environmental certification, thoroughly solving the industry hidden danger of metal particles silicone grease corroding components.

Ancham AS3702 Thermal Grease—Full-scene Application Coverage, Redefining Thermal Management

From micron-level temperature to kilowatt-level power modules, AS3702 is suitable for:

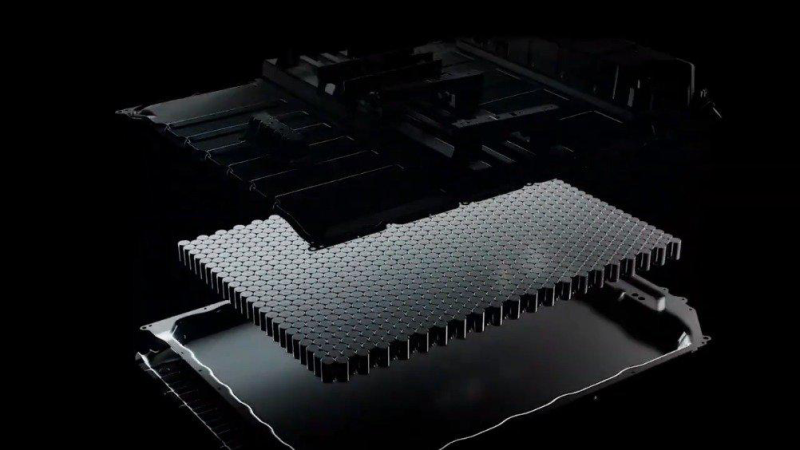

Vehicle Electronics: Battery Management System (BMS), Motor Controllers (with vibration wide temperature range) Supercomputing Hardware: GPU/CPU Cooling (low thermal resistance to enhance overclocking potential)

Industrial Equipment: Inverters Printer Heads (resisting pulverization to extend maintenance cycle)

Consumer Electronics: 5G Base Station RF Module, MiniLED Backlight (precise thin coating overflow)

Why is AS3702 the engineer's first choice compared to competing products?

"Heat dissipation failure is the chronic cancer of electronic products" - Ancham offers a remedy with AS3702! Ancham New Material will meet the technical procurement needs of electronic manufacturing, automotive electronics, and communication equipment enterprises, ensuring that products always remain at the forefront of technology, providing a lasting innovative adhesive product portfolio for/industrial customers!