In the modern electronic and electrical industry, printed circuit boards (PCBs), as core components, directly determine the quality and lifespan of end products However, harsh environmental factors such as humidity, salt fog, chemical corrosion, extreme temperatures, and dust and mildew are constantly threatening the stable operation of PCBs and their components, to circuit short circuits, signal distortion, component corrosion, and even system failures. Ancham® AP9502 polyurethane conformal coating, with its excellent insulation, wide range, outstanding chemical resistance, and convenient processing, effectively enhances product long-term reliability and extends service life, providing reliable one-stop solutions for electronic engineers. This solution aims elaborate on how AP9502, with its superior material properties, provides comprehensive and reliable protection for electronic products in various application fields, significantly improving product quality and market competitiveness.

Core technical challenges and Ancham®AP9502 solutions

1. Challenge: Performance degradation and insulation failure in high-temperature environments

• Problem Description: Many electronic devices (such as automotive engine compartment controllers, industrial motor drives, high-power power supplies) generate a large amount of heat operation or are exposed to high temperatures for an extended period. Ordinary protective materials may soften, decompose, or release conductive ions at high temperatures, leading to a decrease in resistance and causing faults.

•Ancham®AP9502 Solution:

①Outstanding High-Temperature Resistance: After curing, AP9502 can temperatures up to 135℃ without any degradation in performance. This ensures that the protective coating maintains its structural integrity and electrical insulation even under high-temperature conditions.

②Stable Electrical Insulation: With a volume resistivity of up to 2×10¹⁵ Ω·cm and a surface resistivity of 2.6×10¹ Ω, it provides an extremely excellent insulation barrier, effectively preventing arc puncture under high voltage and electrical migration under low voltage, even in environments with high temperatures and humidity.

2. Difficulties: corrosion and short circuit caused by dampness, salt mist and chemical agents.

• Problem Description: In outdoor equipment, automotive electronics, marine instruments, or industrial control scenarios, high humidity, salt fog, and various chemical solvents ( as cleaners, fuel) can corrode the metal traces and solder joints on PCBs, causing oxidation and corrosion, ultimately leading to open or short circuits.

•Ancham® AP9502 Solution:

①Extremely low water absorption rate and excellent chemical resistance: AP9502 has an low water absorption rate (≤0.15%), which can effectively block moisture permeation. Meanwhile, its polyurethane modified system endows the coating with excellent chemical corrosion, being able to resist the erosion of various chemicals, providing a comprehensive "armor" protection for PCB.

②Excellent adhesion and physical strength: Through the hundred-grid method test, its adhesion reaches the highest grade 0, indicating that the coating firmly combined with the substrate and is not easy to peel off. The pencil hardness of 3H-4H gives the coating good abrasion resistance, which can withstand physical and vibration, ensuring the integrity of the protective layer.

3. Challenge: Uniform coverage of complex PCB board types and process adaptability.

• Problem description: The uneven height and complex structure of electronic components on modern PCB boards put high demands on the coating process of protective coatings. The needs to have good leveling and penetration properties to ensure uniform coverage in all corners without bubbles and without obscuring the solder points that need to be repaired or debugged later.

•Ancham®AP9502 Solution:

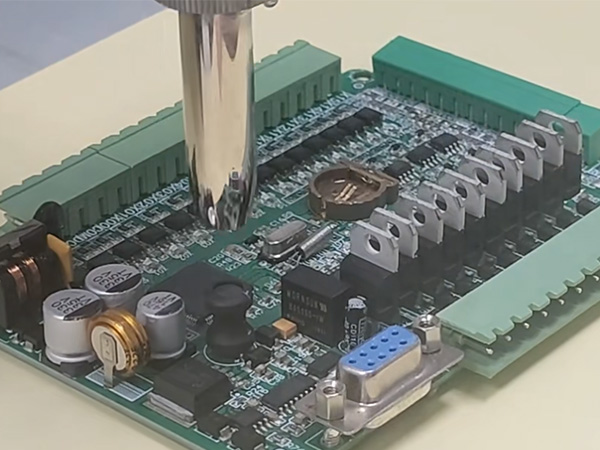

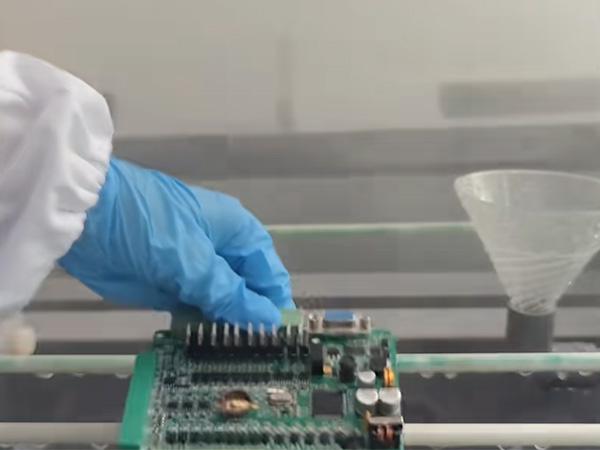

①Excellent process adaptability: The product has moderate viscosity (4-cup 1-25 seconds), supporting various coating processes such as dipping, spraying, and brushing, which can flexibly meet the needs of different production lines.

②Good substrateting: It has excellent wetting on the substrate surface, and no bubbles after curing, which can form a continuous and uniform protective film on uneven surfaces.

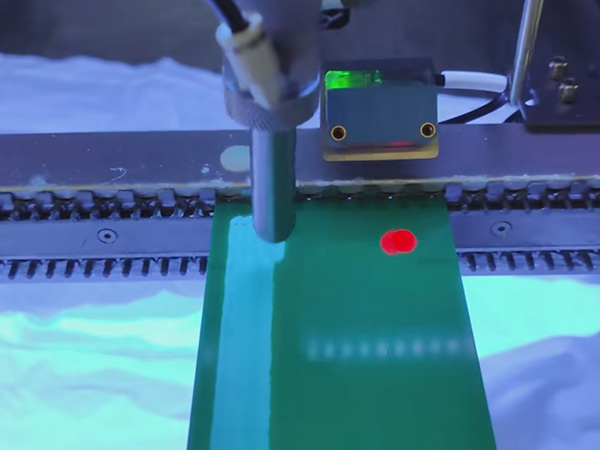

③UV inspection: The coating has a built-in fluorescence property, which can be detected by UV (ultraviolet) light after curing. This facilitates quick and damage-free inspection of uniformity and integrity of the coating during the production process, effectively controlling the production quality.

4. Challenge: Environmental and safety compliance requirements

• Problem Description: With increasingly stringent global environmental regulations, electronic manufacturers must choose materials that comply with directives such as RoHS and REACH.

•Ancham®AP9502 Solution:Environmentally friendly formula: The product does not contain benzene-based solvents, meets strict environmental requirements, and reduces harm the environment and human body during production and use.

Main application fields

•Automotive electronics: engine control unit (ECU), sensors, on-board chargers, etc., addressing high, vibrations, and chemical fluid erosion.

•Industrial control: PLC, frequency converter, servo driver, etc., resisting dust, humidity, corrosive gases and wide temperature variations in factory environments.

•Consumer electronics: high-end household appliances, outdoor audio, drone control boards, etc., enhancing product durability in damp, salt environments.

•Communication equipment: base station filters, power modules, etc., ensuring long-term stable operation under harsh outdoor climates.

•New energy field: inverter, energy storage system BMS, etc., providing high-standard electrical insulation and environmental protection.

Ancham®AP9502 is more than just a coating material; it is a systematic solution to the reliability issues of PCBs across multiple industries scenarios. It effectively addresses the protective challenges that electronic engineers have long faced in product design and manufacturing by striking a comprehensive balance between key properties such as high temperature resistance, high insulation, chemical resistance, excellent processability, and environmental safety.