As electronic products become increasingly sophisticated and miniaturized, and are widely used in harsh environments such as high humidity, high dust, and high corrosion, the-proof coating process has become a critical link to ensure the long-term reliability of PCBs. However, not all areas on the board need or can be coated. For example if connectors, battery holders, switches, debugging interfaces, optical sensors, and other parts are covered with three-proof paint, it will lead to functional failure or performance degradation.

Traditional masking methods expose numerous pain points when dealing with irregular shapes, fine pitches, or mass production:

• Inefficiency: Manual application of is time-consuming and labor-intensive, difficult to automate, and becomes a bottleneck in the production process.

• Lack of precision: Tape struggles to adhere closely irregular components, leading to potential leakage of conformal coating or excessive masking area, compromising protection effectiveness.

• Residue risk: Tape removal may leave behind adhesive residue, affecting conductivity of connectors or the transparency of sensors, requiring additional cleaning steps.

Therefore, there is an urgent market need for an innovative solution that can achieve precise, efficient, and clean. Ancham PM7005 Peelable Tape is designed to address this challenge.

I. How does the PM7005 achieve excellent shielding protection?

Ancham PM7005 is a latex film product specially designed for protection, with its characteristics of liquid spraying, film curing, and easy peeling, perfectly meeting the process requirements of selective three-proof coating.

Application process:

1. Precise coating: Before applying the conformal coating, apply PM7005 peelable adhesive precisely onto the components areas that need protection through manual dispensing or automated spraying equipment.

2. Quick curing: The adhesive can be cured rapidly at room temperature into a tough and elastic mil white film. When heated at 70-80℃, it can be cured within half an hour, greatly improving production efficiency.

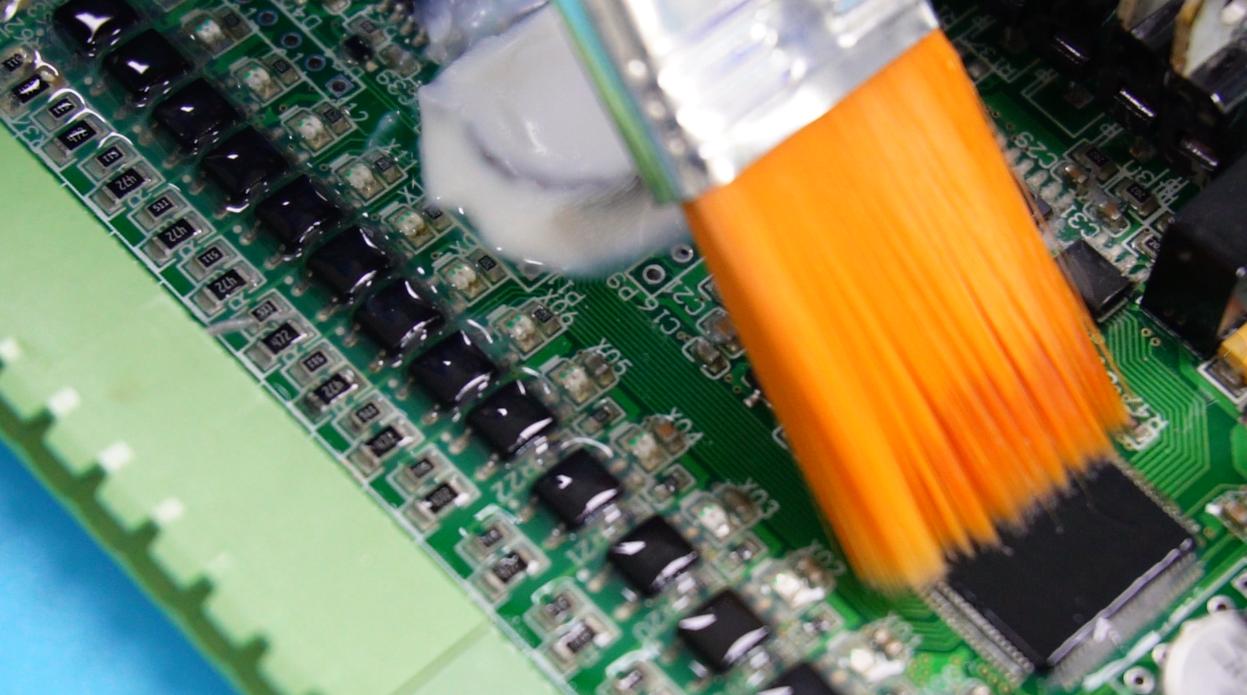

3. Perform conformal coating: Car out conformal coating processes such as spraying, brushing, or dipping. The protective film formed by PM7005 can effectively block the coverage and penetration of the conformal coating.

4. Easy peeling: After the conformal coating is cured, you can peel off the protective film completely and cleanly from the edge, leaving the protected area clean as new without residue.

II. Analysis of the core advantages of the product

Compared to traditional masking solutions, the core advantages of PM7005 are reflected in the following aspects:

1. Ultimate, perfect fit

Advantage: As a liquid material, PM7005 can easily cover any complex shape and precision area, such as the bottom of connector pins and the of irregular components, achieving "no-dead-angle" masking, preventing the infiltration of conformal coating, and ensuring clear and neat masking boundaries.

2. Efficiency improvement automation support

Advantage: The product has appropriate viscosity, which is not only convenient for spraying but also prevents excessive sagging, making it very suitable for automated production lines to high-speed and consistent coating, significantly reducing labor costs and increasing production capacity. The rapid curing property further shortens the process waiting time.

3. Clean separation, reliable

Advantage: After curing, the film formed by PM7005 has excellent flexibility (elongation at break > 500%), ensuring a smooth and separation process without cracking or residue. Its non-corrosive property ensures safe use on various sensitive metal surfaces, guaranteeing the electrical performance and long-term reliability of critical such as connectors and gold fingers.

4. Process flexibility, stable and durable

Advantage: The protective film itself has certain strength and can remain intact during the conformal coating process Its wide process adaptability allows it to form a stable protective layer whether cured at room temperature or accelerated by heating.

Ancham PM7005 strippable adhesive provides an innovative masking solution for selective conformal coating process. It perfectly solves the precision, efficiency and clean issues of traditional methods by precisely converting liquid into a peelable solid film, significantly improving the yield of the final product and the overall efficiency of the production line.