In 2020, Tesla deployed several lithium battery production lines at its plant in Berlin, Germany, and the 4680 lithium battery researched and partially produced by Tesla will be gradually put into operation. CTP module free technology, single cell with larger capacity and 4680 battery can help Tesla manufacture electric vehicles with longer endurance at faster speed and lower cost, so as to maintain the leading position in the industry.

The 4680 is the performance representative of the cylindrical power battery that Tesla has been pursuing. It is different from the square hard shell battery with the widest application range at present. The cylindrical power battery has high technical maturity, high battery consistency and better overall stability of the battery pack after the pack is grouped. The structure is simple and highly standardized, and the monomer energy density is higher.

4680 cylindrical battery is Tesla's new heart. It has to withstand high temperature, water and freezing. Among them, the stability in high temperature environment is a potential danger more serious than the reduction of endurance in winter. At present, the vast majority of electric vehicle accidents are related to batteries and intelligent driving system. The former is the "brain" of electric vehicle thinking and behavior decision-making, while the latter is the "heart" of electric vehicle life and death.

The power battery has large working current and heat production. At the same time, the battery pack is in a relatively closed environment, which will lead to the temperature rise of the battery. Once the "heart" has the problem of unstable high-temperature environment, electric vehicles will burn like fire!

There are two kinds of power battery heat dissipation, active and passive, which are very different in efficiency. The cost required by the passive system is relatively low and the measures taken are relatively simple. The structure of active system is relatively complex and requires more additional power, but its thermal management is more effective.

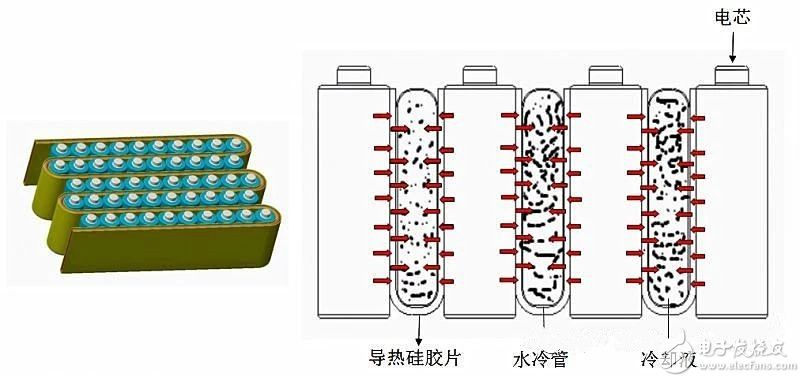

The most obvious disadvantage of cylindrical power battery is the insufficient utilization of cylindrical space. Tesla's approach is to adopt passive heat dissipation and lay the gap with cooling system, which can appropriately alleviate the disadvantages of high temperature resistance and poor safety of ternary lithium. That is, the thermal conductive material of the power battery is installed between the battery cell or battery module, between the battery module and the shell. Silica gel sheet is one of the options with high efficiency and higher cost performance. The heat conducting silica gel sheet has the characteristics of high heat conducting insulation, shock absorption, tear resistance, good seam filling ability and long service life. It can quickly transmit the heat generated by the heat source through the heat conducting silica film.

Compared with the method of using gas as the heat transfer medium, the heat transfer coefficient between the thermal conductive silicon film and the battery wall is high, the heat dissipation is faster and the efficiency is high. The way of using liquid as heat transfer medium has relatively high quality and complex maintenance, which requires water jacket, heat exchanger and other components.

Different power battery structure temperature sensors will be placed in representative positions with large temperature changes, such as the inlet and outlet of air and the middle area of battery pack. Especially at high and low temperatures, as well as areas with severe heat accumulation in the battery pack.

In the actual application of electric bus, due to the large capacity and volume of power battery pack and relatively low power density, air cooling scheme is mostly adopted. For the battery pack of ordinary passenger cars, its power density is much higher and the requirements for heat dissipation will be higher. Therefore, the flexible application of thermal conductive silicon film is a reliable choice.

The heat conductive silica gel sheet can be flexibly applied in the process of battery module packaging or pack, and there is no right or wrong application conflict with the use of gas or liquid conduction medium. While conducting heat, it can cooperate with the above scheme to achieve the purpose of heat conduction or temperature control, which helps to control the temperature of the battery in a relatively reliable environment and avoid the danger of overheating and supercooling to the power battery.