In the electronics/industrial manufacturing sector, silicone adhesive sealants, as key sealing materials, demonstrate exceptional application value due to their unique chemical structures and physical properties. Ancham New Materials' AS3465 is a high-performance, one-component neutral (alcohol-release) silicone sealant that cures through moisture reaction technology. It forms a flexible, durable elastic adhesive layer at room temperature by reacting with moisture in the air. Suitable for sealing and bonding a variety of materials, including general plastics, glass, metals, concrete, and ceramics, AS3465 is an indispensable high-performance sealing material for the electronics, automotive, new energy, and aerospace industries.

|

|

Thixotropy and Anti-sagging. AS3465 exhibits excellent thixotropic properties, presenting a paste-like consistency that prevents sagging after application. It can be directly used in FIPG (Formed-In-Place Gasket) sealing processes, suitable for vertical surface application, ensuring precise sealing in complex structures.

Outstanding Mechanical Properties.

With a low glass transition temperature and a helical molecular chain structure featuring weak intermolecular forces, AS3465 demonstrates excellent low-temperature flexibility and high-temperature stability. After curing, it forms a highly tough elastomer with a fracture elongation rate of ≥600% and excellent impact resistance, capable of withstanding dynamic loads and vibrational environments, such as seismic structures and elastic seals. It effectively absorbs external stress, preventing cracking or detachment due to environmental changes.

Exceptional Thermal Stability.

The unique chemical structure of AS3465 provides high thermal stability, allowing it to resist molecular chain breakage or decomposition even under prolonged exposure to high temperatures, ensuring outstanding performance. It maintains elasticity within a temperature range of -50°C to 200°C, remaining non-brittle at low temperatures and non-flowing at high temperatures. Suitable for harsh thermal cycling conditions, it ensures long-lasting sealing performance.

Moisture Barrier and High-performance Bonding Seal.

The molecular structure of AS3465 can achieve a balance between breathability and sealing through crosslink density regulation. Its low surface energy enables it to maintain adhesive strength in humid environments while preventing moisture penetration, avoiding sealing failure caused by freeze-thaw cycles. In electronic packaging, it simultaneously prevents moisture ingress and releases internal stress, extending device lifespan.

Acid-Base Corrosion Resistance and Strong Environmental Adaptability.

AS3465 is inert to acids, alkalis, salts, and most organic solvents (such as gasoline and alcohol), making it suitable for sealing applications in corrosive environments like laboratory equipment. Additionally, it is a solvent-free formulation that complies with RoHS and REACH environmental directives, containing no harmful substances like halogens.

Excellent Electrical Insulation Properties.

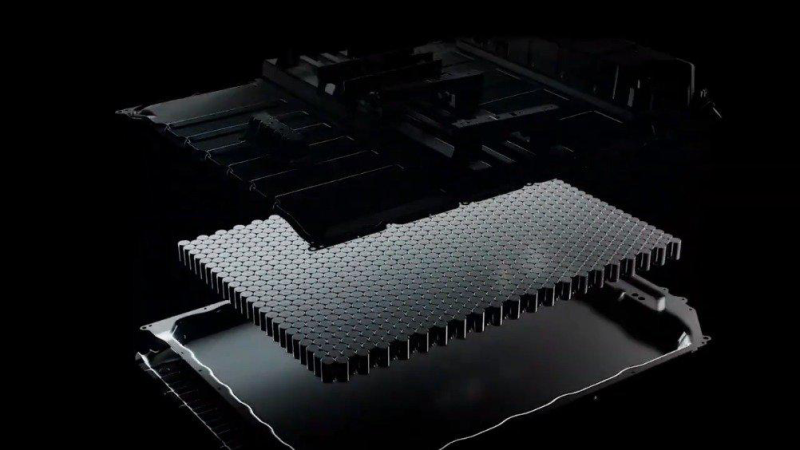

AS3465 possesses excellent dielectric strength and insulation performance, with a volume resistivity >3.41×10¹⁴ Ω·cm. Its electrical properties are minimally affected by temperature and frequency, and it exhibits outstanding corona resistance. This makes it the preferred sealing material for power equipment and new energy vehicle battery packs, effectively preventing arc, leakage, and other safety hazards, providing reliable insulation protection for electronic components.

AS3465: Analysis of Electronics/Industrial Applications

Auxiliary Fixing and Encapsulation of Electronic Components

Application Scenarios: Fixing sensitive components on PCBs (e.g., capacitors, transistors); potting power modules; elastic bonding of sensors.

Application Advantages:

Precise dispensing control for fixing precision electronic components using its thixotropic properties, avoiding contamination of surrounding parts.

The elastic modulus of AS3465 effectively absorbs external vibrations during component assembly without interfering with the detection accuracy of sensitive components.

Sealing of Electric Heaters and Instrument Components

Application Scenarios: End sealing of electric heating tubes; waterproofing of instrument panels.

Application Advantages:

Annular sealing of metal-ceramic joints in electric heaters, with high-temperature resistance ensuring long-term use without cracking.

Using the FIPG process to form a continuous sealing gasket for instrument housing seams, replacing traditional rubber gaskets and improving production efficiency by over 30%.

Sealing of Transformers and Power Equipment

Application Scenarios: Sealing of transformer cores; waterproofing of cable terminals; insulating coatings for high-voltage electrical equipment.

Application Advantages:

Applying adhesive to the flange joints of oil-immersed transformers to form an oil-resistant elastic sealing layer, preventing leakage.

Encapsulating stress cones at high-voltage cable joints, with corona resistance effectively preventing partial discharge.

|

|

Providing seismic sealing for power equipment, ensuring long-term reliability in vibrational environments like substations.

FIPG Sealing Process Applications in Mechanical Equipment

Application Scenarios: Sealing of electronic control module housings; flange connections of motors; seam sealing of equipment pipelines.

Application Advantages:

Replacing traditional gaskets in the bottom shell sealing of automotive power battery electronic control modules, achieving zero leakage and resistance to corrosion and high temperatures.

Providing elastic bonding for motor flanges, with excellent chemical resistance to avoid glass breakage caused by temperature differential stress.

The compression-rebound performance of AS3465 compensates for the decrease in sealing pressure caused by mechanical connections in equipment pipeline joints, achieving stable bonding and sealing.

With its comprehensive performance advantages and wide application adaptability, AS3465 has become an indispensable high-performance sealing solution for modern manufacturing. Ancham continues to research silicone adhesives, ensuring its products remain at the forefront of technology and providing electronics/industrial customers with innovative adhesive and sealing product portfolios for lasting performance.