On the afternoon of May 16, the State Administration for Market Regulation issued a notice on its official website, requiring Tesla to recall some batches of Model3 and Model Y models produced during 2021.10.19-2022.04.26 within a time limit. The number of recalls reached the highest value since the localization of Tesla, with 107,300 units.

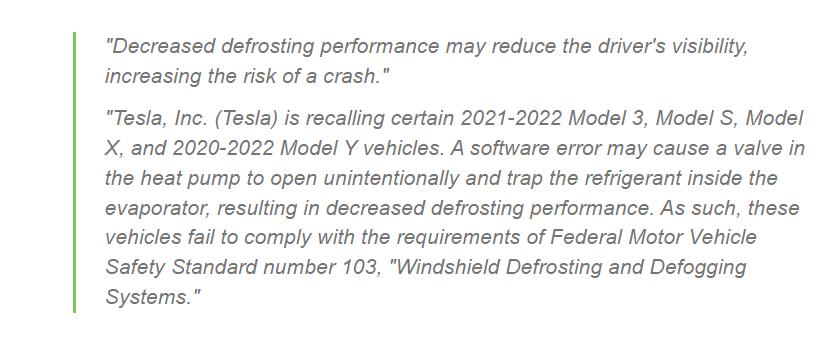

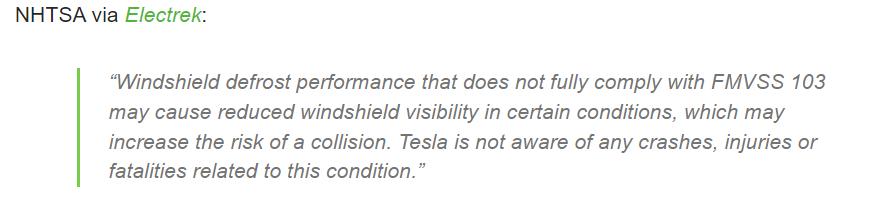

The National Highway Traffic Safety Administration, NHTSA on May 10 ordered Tesla to recall some Model3 and Model Y models. The reason and the domestic recall problem is the same source, are the central control screen lag or crash problem caused by the Heat Pump Issue of the car machine. Tesla's official statement showed that the central processor of the infotainment system may not have cooled enough, causing the CPU to slow down and display a slow central touch display.

In short, the MCU heat treatment capability is not good!

Tesla's solution is to upgrade the software, which controls the frequency of the MCU and the scheduling behavior of the software through the upgraded system to avoid high temperatures. This is the same as some mobile phone manufacturers.

Tesla's history of MCU program changes

In the current new energy vehicle track, there are many brands that achieve mass production and delivery, but among the brands that are "intelligent driving" and have a wider range of users, Tesla is the largest and most anticipated brand. Since the release of Model S in 2012, Tesla has established a perfect management system at a very fast speed. With an extremely avant-garde management concept and bold investment measures, Tesla has quickly surpassed Volkswagen, Toyota and other brands to become the top of the market value.

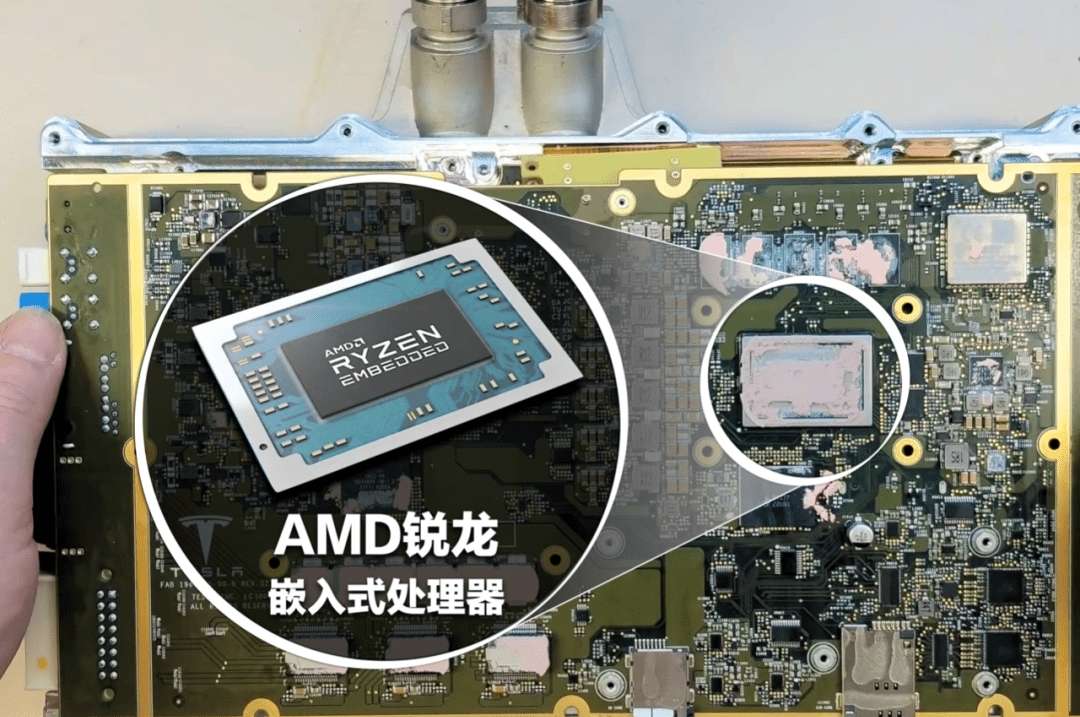

At the end of 2021, a high-performance version of the Tesla Model Y was delivered, and with AMD's Ryzen high-performance processor and independent graphics card, Tesla built the truly strongest car machine. At about the same time, the 2022 Model3, still assembled in Shanghai, has the same car

Since its launch in 2016, the Model 3's car chip has been replaced with a more stable Intel Atom A3950 processor in 2018.However, after a few months, the owners of the complaints came in, using the integrated graphics card + eMMC solution, its processing ability and read and write speed can not meet the more needs of users, even the basic driving process is affected.

The main computing chip Intel Atom A3950 was released in 2016,14nm process, integrated HD 505 graphics card, computing power 187GFLOPS.Simple PC installation test, the game performance even the minimum demand is not even guaranteed.The Tesla machine is equipped with 64GB eMMC, which improves the reading speed and also exposes the disadvantages of its short life. There is no clear official replacement cycle, and the replacement process is more complicated, which cannot match the service life of the car, which is not the optimal choice for Tesla, which is highly dependent on the control of the car.

As a result, starting from January 13,2021, Tesla has recalled some Model S models due to numerous complaints from its users.

The solution of the third generation of Ryzen chip makes the much-criticized performance problems of users be solved. The customized and embedded AMD chip, integrated Vega8 high-performance graphics card, and the TDP power consumption has directly increased from more than 12W to about 175W. Whether CPU or GPU, the performance has been greatly improved compared with the previous generation.

However, the configuration system, which should have been praised by users, faced a large recall less than a quarter after the launch. Few of the MCU solutions that can operate stably in the ambient temperature range of-40°C~105°C selected by Tesla are quite different from the maximum temperature requirement of 150℃, and finally fell on its proud processing performance.

According to Tesla found that the recall was the fourth time in China since 2022, and about 275,800 cars were recalled.In the North American market, this is the 10th recall, involving potential windshield defrosting, failure to open airbags, and regulatory irregularities, but most of them are made through OTA wireless upgrades.

Consistent with the preface, Tesla controls the maximum operating frequency of CPU through the system OTA upgrade, so as to solve the heat dissipation problem of MCU while properly reducing the processing performance.

Effect of the MCU Heat Pump Issue on the driving process

Tesla integrates reversing images, driving status, warning lights and front windshield into the central control screen, which carries a considerable amount of information and the vehicle's electric control devices. Various complaints in the United States and China showed that the MCU Heat Pump Issue delayed the interactive response of the central control screen, some applications were slow or failed to start, and the central control screen could not be displayed.

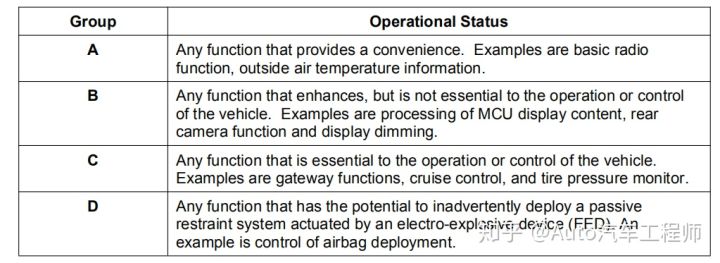

A domestic new energy vehicle brand conducted a careful analysis of Tesla's enterprise standards, and its products were divided into four groups according to their functions.

Group A products are defined as: any convenience function for the driver or passenger, such as radio, external temperature information, etc.;

Group B products are defined as: any function that improves the operation or control of the vehicle, but is not decisive in the operation or control of the vehicle, such as the MCU of the display components, the rear-view camera, the display brightness adjustment, etc.;

Group C products are defined as: any decisive function for vehicle operation or control, such as gateway, cruise, and tire pressure monitoring;

The Group D product is defined as any function of a passive restraint system that may inadvertently be deployed and driven by an electric explosion device (EED), such as airbags.

Vehicle safety requirements should be improved from A to D layer by layer, and the display and response of the large central control screen are abnormal, which should be attributed to Group B.Once the display or touch control failure of the central control screen occurs, it will affect the display of the reversing image and the driving state. The warning light and turn signal cannot flash normally, the steering signal in the car is abnormal, and the window automatic defrosting function cannot be activated.It may be impossible to predict the driving situation, resulting in greatly improved safety risks.

Group B products are not decisive in the operation or control of the vehicle, but the impact on driving is beyond doubt.Novice drivers or drivers with poor psychological quality may overreact in the face of sudden problems, resulting in unpredictable consequences.On the other hand, due to the high power consumption of the new MCU scheme, the vehicle range is affected to a certain extent. The car review blogger test shows that the new Model 3 range will be reduced by about 3.5%.For Tesla itself, the frequent fault red lights will also have a certain impact on its own brand influence and performance.

Tesla's MCU thermal management scheme

How to effectively deal with the high TDP power consumption of chips has always been a hot topic in the field of communication and computing. The PC and NB industries have been trying to solve the problem through heat conduction, heat dissipation and frequency locking. Air cooling and water cooling are the mainstream cooling solutions, and the practice of air cooling has been used in mobile phone manufacturers.

New energy vehicles based on the concept of intelligent driving have been developed for nearly a decade, but the thermal management of vehicles and machines has always been stagnant in the stage of heat conduction and material heat dissipation, which is undoubtedly an uncoordinated and backward practice for the vehicles and machines due to the gradual improvement of performance and power consumption.

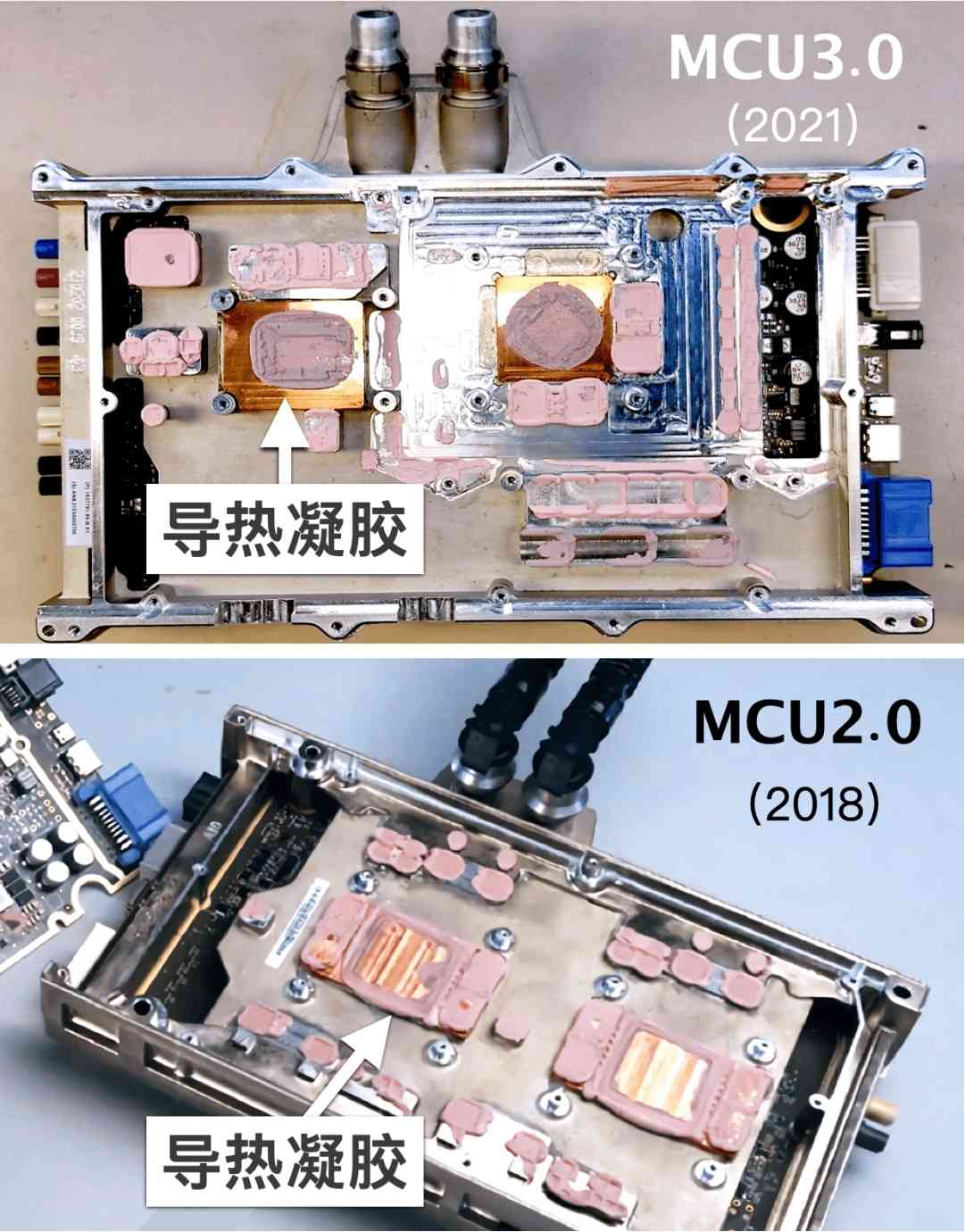

In the dismantling of the 2022 Model 3 car machine, car critics found that Tesla's third-generation MCU chip has not changed in the thermal conductivity materials. After removing the screws and opening the shell, the pink thermal conductivity material on the metal protective cover occupies a large area, which is similar to the internal structure of the second-generation MCU box.

Due to the differences of components and processes, the internal structure of MCU is very different in the size of the workpiece, and the gap between the heating components and the casing.Thermal conductive gel in conventional storage conditions as the form of paste, metal oxide reinforcing silicone rubber heat resistance filler, can fully adapt to different areas and gap daub and filling, coupled with a mature process, low cost, as a "heat conduction" in heat management, should be the most ideal material.

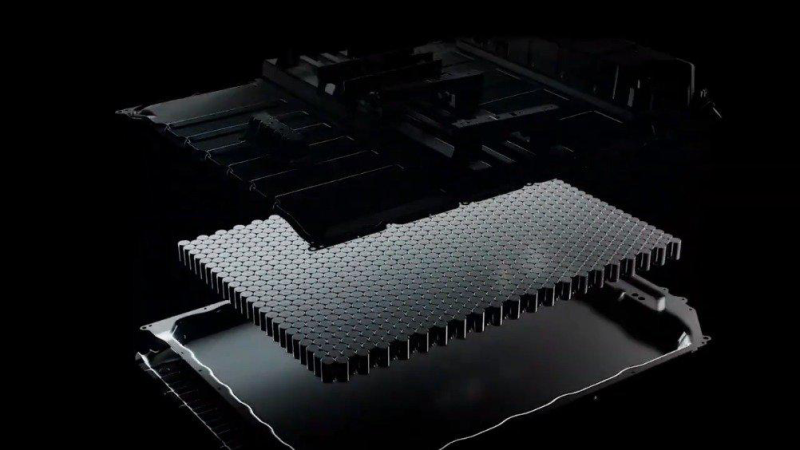

In addition to the MCU, the filling seam of the 4680 battery and the upper and lower layers are also pink hot conductive silicone, the same application also appears in the structure of BYD blade battery, it can be seen that hot conductive silicone is an irreplaceable thermal conductive material for electric vehicle manufacturers.

From the perspective of the automobile industry, in the long-term development, the industrial application standards for thermal conductivity materials have not been refined to the parameter level of thermal conductivity. National or regional regulations for the application of thermal conductive materials for automotive interior and external accessories. The participation degree of the intelligent driving system in driving assistance varies. The system configuration of the car and machine is mostly used in the interaction of the central control large screen, and entertainment and navigation account for more than 60% of the application frequency. Therefore, the MCU of car companies has almost never had more than TDP power consumption of 120W, and Tesla has assembled such high performance and high power CPU and GPU with an exception. Therefore, it can be concluded that Tesla has ignored the synchronous optimization of the thermal management scheme after the MCU upgrade.

What determines the thermal conductivity of silicone ?

There are many kinds of materials used for thermal conductivity. In recent years, the most popular one is graphene materials, which have 5300W / mK ultra-high thermal conductivity, and graphite thermal conductivity film has already been industrialized. However, the ultra-thin graphene thermal conductivity material cannot fill the gap between the chip and the radiator parts. Once there is an air gap, the thermal conductivity will be greatly lost. This is why the heat tube is worse than the copper bottom. Theoretically speaking, if the graphite thermal conductive film is thick enough to fill the gap, and apply glue, the above drawbacks can be avoided. But the expensive cost and complex processes can not be favored by the electronic manufacturing industry.

Make the best use of materials, more mature technology, more developed industry of organic silicon is still the "hot property" in the thermal conductivity materials.

In terms of the formula, the main material provides heat resistance, adhesion and curable properties, and especially the metal oxide fillers represented by alumina provide heat resistance and reinforcement. Therefore, different formulations of silicones will produce different thermal conductivity.

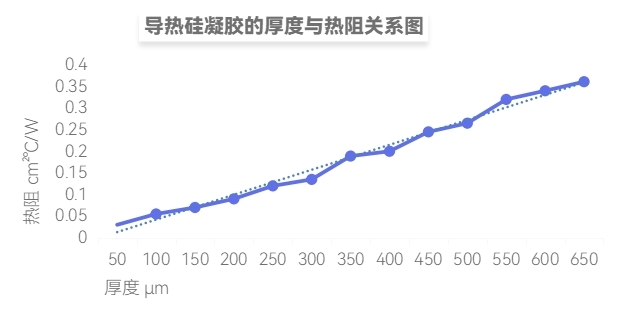

From the application point of view, under the condition of unit thickness, unit area, the higher the thermal conductivity of the material, the lower the thermal resistance value. However, the thickness after applying the glue varies according to the spacing of the filling gap, so the silicone with the same thermal conductivity, the higher the glue thickness, the worse the actual performance of the thermal conductivity.

Such applications are the first to be proven in vibrant consumer electronics sectors such as PC / NB, which can be jade, and automakers have tested similar results when they misappropriate similar solutions. The fourth-generation Toyota Prius THS IV electric drive IGBT module uses a water-cooled plate to double-cool the IGBT, while the rigid interface between the module and the cold plate reduces the contact thermal resistance by conducting thermal silicone grease, which reduces the electrical loss by 20%.

How does Ancham save theheart disease of electric cars?

The thermal conductive silicone fat of the vehicle and machine computing module is divided into multiple levels in the performance level, with the thermal conductivity ranging from 4W / m · K to 12W / m · K, which can take into account the dual identity of "economical" and "overbearing president". At the level of thermal silicone fat, Tesla has many improvements to choose from.

The experience of semiconductor manufacturers is learned. Intel's strategic front-end product in graphics cards, GUNNIR, uses 7921 thermal silicone grease with a thermal conductivity of 5.73. The difference between new energy vehicles and consumer PC in the computing unit lies in the temperature difference of the heating module. The temperature range of the vehicle gauge chip is generally between-40°C and 150°C, which is higher than the 0°C~80°C of the consumer chip.

Based on the operating power of automotive entertainment chips, the third-generation Ryzen chip selected by Tesla has a single and high performance, which can guarantee the temperature operation of up to 105℃, which is close to the limit temperature of the current MCU. Therefore, judging from the core parameter of thermal conductivity, ideally, 8W / m · K thermal conductive silicone has been able to effectively meet the chip thermal conductivity requirements of electric vehicles.

For the application of vehicle computing module, Ancham has developed a product series of two silicone systems, single component and two-component silicon system. The thermal conductivity of two-component thermal conductive silicone can reach more than 8W / m · K, and supports users to participate in the whole process of the product development and customization process. In terms of hardness, flexible product formula design, can achieve the full paste type of intermittent filling effect after curing, in the case of ensuring that the air can not enter, the thermal conductivity of the material application end to the extreme.

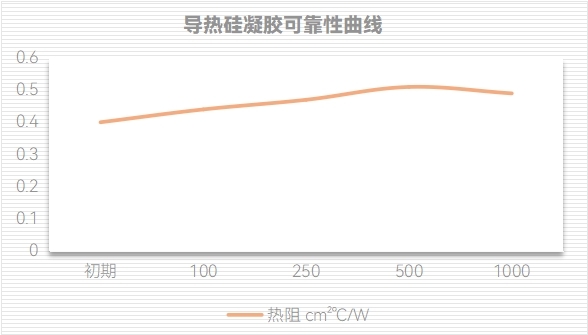

Take AS4680 as an example, in the process of extrusion application, the high extrusion rate can achieve the thinnest interface thickness of 0.1mm (BLT), so as to achieve a low thermal resistance value of 0.5 c m ²℃ / W, efficient heat dissipation and improve the chip reliability. The Ancham tester found that when the compression rate is set at a 30% limit, the long-term reliability of the product exceeds many first-line brands, and the thermal impedance value is always maintained at 0.5 c m ²℃ / W, which can effectively solve the thermal conductivity problem of the vehicle MCU.

After the glue is applied, the rheological characteristics enable it to complete accurate coverage within the contact interface range, and the thickness of the solidified material is more uniform. At the same time, the two-component formula design makes the volatile content of AS4680 low. It is a thermal conductive material developed for the vehicle-level vehicle machine chip, and is a targeted therapeutic drug for theheart disease of electric vehicles.

Ancham's product layout in the field of new energy vehicles is broader, from BMS battery management system, battery module, OBC, to charging pile. The product involves polyurethane, silicone, acrylic acid three major systems, the applications include thermal conductivity joint filling, flame retardant sealing, three prevention coating, structural bonding and thermal conductivity irrigation and sealing. In response to the lightweight design needs of the vehicle, it can break the high temperature challenge of the battery module and effectively protect the stable operation of OBC / DC-DC, core modules and BMS.

Epilogue

The selection of any material can not bypass the cost constraint factor. In the increasingly fierce competition of electric vehicles, every enterprise wants to dig out more profit margins from the cost accounts. It is an indisputable fact that the localization of high-end thermal conductive silicone is replaced. Many manufacturers go forward together from both technology and application ports, and the barriers set by international trade in high-end raw materials are also broken through with the technological progress of Wanhua, Sinochem and other giants.

In the core hinterland of electric vehicle manufacturing, the domestic high-end thermal conductive silicone with higher performance and cost performance is still the most ideal thermal conductive material for the on-board MCU. Tesla's inappropriate choice at the beginning of the engineering design did not nail the thermal conductive silicone on the shame column. Silica is a material world worth paying for more time and energy to explore, and we look forward to making more amazing discoveries from material manufacturers.

Note: some of the pictures in this article are from the Internet content, and will be deleted immediately in case of infringement.